In the past I’ve written about some of my days at the former Nottingham Trent Polytechnic as a young apprentice compositor in the print trade. Those days were bitter-sweet in many ways but as is often the case with these things, the pleasant and funny memories tends to shine through of good friends and times, rather than the tension and worry that accompanied and often characterised that era.

Very much the flip side of that period were the days spent in my regular job as an apprentice compositor at the small jobbing printing company where I was gainfully employed for six or seven years.

As a school leaver I had little clue and even less instruction in how to begin a career. I recall having vague dreams about being a journalist, working with words, but that was about it. That faint notion was dashed on the rocks of indifference emanating from school and my own parents. For the best part of my first year in employment I somehow became very happily employed at Trent Bridge Cricket Ground on the ground staff – a job I loved and enjoyed – but which sadly died in a round of job cuts for the then-stricken Notts County Cricket Club as Christmas approached. What followed was probably the worst three weeks of employment in my life at a gents outfitters in Nottingham named Horne Brothers.

As an extremely shy young teenager I was ill-placed for the job of trainee salesman afforded me in the slightly up-market city centre store. I died a death or two in there and remember vividly, counting every single quarter hour chimed out through the days by the Nottingham Council House clock, ‘Little John’. What a relief it was when I was informed that my services were no longer required after my third Saturday in the job which had seemed to last at least four days alone.

Shortly afterwards, a break came along in the form of an apprenticeship offer in the print trade and being opportunistic by nature and relishing the idea of ‘working with words’ I grasped the chance and in May 1976 began the long road towards being a journeyman compositor. It was not an auspicious start however.

My very first task on my nervous first morning was to unravel a huge mountain of page cord – special twine that was used to tie loose lead type characters together. This was certainly not what I had expected and I seem to recall this task lasting several days into my first week. What a huge disappointment it all seemed after all the talk of operating industrial cameras, developing film and all the other interesting aspects of the job I had been promised. I was very quickly about to learn what the term ‘paying your dues’ was all about.

The weeks went on with many of the worst and dirty jobs being given to me, the new apprentice. One classic was sweeping the floors and separating the lead type which had been dropped on the floor, from the vast amount of cigarette ends, so that it could be re-melted in the Monotype Caster machine molten pot or sent off in sacks to be weighed in for credit. The last task was set as a punishment for not complying with a senior work colleague’s command for me to set the type for his ‘foreigners’ – illicit private jobs which were carried out on the side by certain workers for their own profit.

It wasn’t all maudlin and grief though. There were some great and very funny moments when looking back at what was a fairly bizarre working environment at times. During the 1970s everything ‘went’ at work and the working days were often interspersed with many a wicked practical joke and just general moments of sheer lunacy. I recall one day walking into work at 8.15am and seeing two printers operating small Multilith printing machines dressed in full bear outfits, the remnant of last night’s fancy dress disco. At lunch time we marched down to the main road shops with them in our midst and stopped the incredulous traffic so that the bears could go for their fish and chips ‘picnic’.

The characters were many. In the machine room was a foreman who was clearly still living during WWII. I recall a fellow apprentice being instructed in the finer arts of bayonet use up against the canteen wall with the aid of a pool cue by ‘Lenny’, his thin, cruel moustache all a-bristle in a serious ‘Dad’s Army’ parody. They don’t like it up ‘em son.

Another employee, a guillotine operator, who as anyone with a faint knowledge of the print trade knows are the industrial equivalent of the goalkeeper or wicket keeper (a hint of madness being present) owned the world’s largest collection of pornography which he jealously guarded. He also appeared to own the global record for the most consecutive days use of a work shirt without troubling the laundry load, though I did come across others contenders for this dubious crown in subsequent years unfortunately.

Another character was in the habit of including two hard boiled eggs in his lunchbox each day. The same exact daily routine would occur of the eggs emerging and him cracking them open lustily on his knees simultaneously. That was until ‘someone’ replaced them with two raw eggs one day…

I have dear memories of Neil and Albert, the only two other names I shall mention here. Neil had been the apprentice compositor just prior to me and was a great mate, a good help during my early floundering and a superb footballer who I appeared to share an almost telepathic understanding with during lunchtime games of football in the car park. Albert was quite something else and I often still think back to his wisdom and the things he taught me. No longer with us, I owe him a lot for he taught me the right way to do things and passed on years of expert knowledge and mastery of the trade and life in general which not all journeymen did in those long ago days.

Being a compositor in those days was an exacting business. I recall inquiring of Albert, who was probably as accomplished a ‘comp’ as it was possible to be, one day, whether I would be able to ‘get away’ with a shortcut or two on a job I was typesetting by hand. His answer? ‘There is only one standard, Stuart’. His meaning was clear, that there should be an uncompromising attitude towards the work and that to learn to do things exactly correct with excellence was the way forward. It was an invaluable lesson for me as a seventeen-year old and one that I’ve remembered ever since. This was but one recognisable interchange but there were so many over the years.

The owner of the business himself was something of a madcap character though looking back, a very decent man. Imagine someone with an overwhelming case of ADHD and wearing a huge voluminous dress shirt and expensive but ill-fitting pin-striped suit that buried his thin frame. He also wore those bracelets on his upper arms that hold the sleeves of one’s shirt up, something I’d never seen nor have since. His father had been the chairman of one of the local professional football clubs in Nottingham and was chiefly famous for signing a world class England centre forward in ~Tommy Lawton for the then lowly team. Interestingly some of the fifties artifacts of that amazing deal were to be found stashed away in draws in the factory.

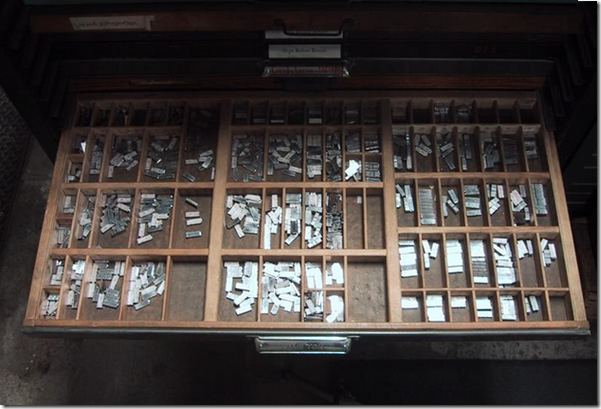

Many of my early days in the job were blighted by being banished to the caster room to operate the Monotype Caster machine. This piece of fairly remarkable engineering was over a hundred years old at the time and was subsequently to find a home in a museum in Wales as newer technology rapidly came in. In the next door office was the equally extraordinary Monotype Keyboard which ran on compressed air and needed the muscles of a weightlifter to punch the keys on the multiple alphabets on display. In a piece of justified type matter, every single line end would require a reading from a spinning drum to be made and a calculation submitted to share the correct amount of space out between each word. Just think about that when you’re next using Microsoft Word.

The end product from the keyboard was a scroll of perforated tape which would then be submitted manually to the caster. The caster would then ‘read’ the configuration of the perforations and via about four million moving bits, turn a pot of molten metal into lines of type made up of individual letter characters. Looking back it really was a tremendous piece of early technology which had at the time replaced veritable armies of compositors setting type letter by individual letter. Although very satisfying, I hated the job, mainly because of the conditions. The room was tiny and made of drab breeze blocks with a tiny slit of daylight coming through a window which looked onto some drab and lifeless flats. The huge cacophony of noise from the caster would reverberate around the brick walls and sear into my brain, in spite of the large ear protectors I uncomfortably wore in the oppressive heat. Due to the great noise created by the machine, the door to the tiny room always had to be closed in order not to disturb other worker’s concentration. This would play on my claustrophobia and add to my private hell.

There were legions of stories about caster machines and most of these were of what we called ‘splashes’. If you can imagine molten lead being hurled at your bare skin you can begin to understand how fearsome this could be. Most of these incidents caused minor burns but stories were many of caster operators emerging dazed and disoriented from the vicinity of a caster covered in ‘suits of armour’ from a wildly spinning caster with molten lead, antimony and tin flying several feet in every direction.

Some light relief was added with the very welcome lunchtime football games in the car park which would invariably be set up as ‘Comps v The Rest’ and using upturned wooden pallets for goals. Scores, tables and leading scorers would be kept and it was all a fairly serious business. So serious was it that I managed to have the guillotine operator sent to hospital with dislocated fingers because of a crash landing on tarmac after a particularly physical body check by yours truly. Nobody seemed to mind, including importantly, the guillotine operator it was all part of the fierce rivalry.

Time moved on and so did the print trade. The little company began to see lesser days and it was time for a few people to leave, myself included. The redundancy call came as something of a shock but of course it was the right thing, it was time to move on. Occasionally I receive a brief reminder of those days by bumping into an old work colleague. This always gives me a warm feeling. Another more curious occasional reminder is when I see lead type, setting sticks and cases of type on display at craft and book fairs and museums. It really does seem like another world to me these days but nevertheless brings some pleasant memories hurtling back.

Now this is kind of spooky, given that we recently ascertained we were probably in the Imperial at Gaffa gigs at the same time… I too spent many hours (in those Gaffa days, in fact) in a hot-metal comp room, fighting with page cord, dissing, avoiding metal splashes from the casters, bagging loose type and burning my hands using a gas flame to loosen the glue on zincos so we could lift them off the blocks and recycle them. The constant ‘clack clack clack’ of the casters is one of those sounds that’s gone forever, like the ‘whumph’ of the old reciprocating flatbed presses, or the various noises of the Platen. I still have a composing stick somewhere around the place… I did spend some years learning film assembly and repro camera work, and got good just about the time the Macs and the desktop scanner arrived and the darkroom closed forever…

Hello again! Certainly another co-incidence, we seem to have a few things in common! I have to say it’s good to talk to another ex-comp, I had begun to think that era of my working life was a figment of my imagination! You bring back quite a few memories for me there, those sounds stick in your head forever it seems don’t they. Maybe you enjoyed the job in those days like I did? My memory tells me that it took maybe a couple of years just to be practised in handling type properly, let alone the other many and varied skills required. Like you probably experienced too, the change in technology appeared on the horizon like a tidal wave in the small company I worked in. I’d just spent four long years at Trent Polytechnic learning hot metal composing only to find that within around a year or so it was completely useless. Criminal really when you think about it.

I note a few musing yourself on the subject on this post: http://thequizzicalobserver.blogspot.com/2010/11/social-networking.html and look forward to having the time to take a good look around your own site. There looks to be some very good reading there. Printing being the small world that it was, I’m sure we will have some common acquaintances from the trade and/or college. Whereabouts did you study/work could I ask? I was at Trent Poly 76-80 and employed at Barnes & Humby, a small company off Carlton road. Here’s a related post from last year when I found some fellow old comps I studied with at the time: https://stuartfrew.wordpress.com/2009/09/04/thursday-nights-reunion-time/

Best wishes, Stu

Here’s something even spookier… I was a comp too. A bit earlier than you guys but I did five years at Trent Poly as well.

Must be the love of words that sees us all ending up as bloggers.

Certainly more than a coincidence! Good to be talking to another fellow ex-comp!

The same reasons I have to blog under the alias cause me to be a bit reticent – will happily explain over a beer sometime – but suffice to say the name of Barnes & Humby is very familiar and I worked not far away myself, just off Sneinton marketplace. I wasn’t technically a comp, I’d better confess, I was trainee management, but the gaffer (whom I had the privilege of referring to as ‘Dad’) believed in starting on the shop floor. He’d been a comp himself, apprenticed under my grandfather at the Grosvenor Press down south. For a few years all three of us worked together, which was quite a privilege.

Alan – another one who recalls hot metal? It’s a small world!

I too used to be a hot metal compositor many moons ago. It must be about 28 years ago since I last touched a hot metal news page; arranged linotype slugs on a galley or used a ludlow machine on the newspaper I then worked at. The newspaper switched from hot metal to cold metal. I was retrained as a computer keyboard operator and paste-up artist. I finally got out of the trade three years later. Twenty five years ago.

I spent six years as an apprentice compositor before gaining my stripes. Looking back it was a skilled job which needed due dilligence. There was a certain amount of comaradarie and a host of characters (human). As a jobbing compositor I moved around a bit. Even spent two years as a compositor in Australia. Having a skill was my passport to emmigrating to Australia by ship as a 10 pound Pom. For that I will always be grateful. I must admit, apart from the newspapers I worked at, the work was pretty tedious, not to say unhealthy, what with the lead and ink one had to work with all day. I haven’t met a fellow compositor for years. Just thought I’d post this, as I am at a lose end on this cold Sunday afternoon. Cheers.

When I started my apprenticeship at Tresises Printers in Burton-on-Trent, I didn’t really know what a compositor was. Back in the day (1977) there were plenty of career choices. My fisrst day was spent learning the layout of the type case. My boss Robert, having lent me a spare apron, complete with ink and solvent stains, gave me the task of sorting a dissing board of Spartan to sort into the case. I was soon enrolled in to the ‘foreigner’ gang, doing jobs on the sly for a bit of extra cash – Saturday mornings were best as the foreman was never there. Having picked up the name of Smike ?? I was quickly fast-tracked to the wonders of Linotype operating while still studying in the dungeons at Green Lane College of Art in Derby – one day of day day release and an evening class on the 518 printing City and Guilds course under the immortal Jack Band for four years.

As apprentice I was responsible for the important tasks of, inking up the proof press, sweeping the floor, changing towels in the toilets, cleaning the mags of the Linotype with the giant toothbrush and giving the spacebars a good clean with graphite. The memories are flooding back.

Melting the metal was a challenge . . .throwing in a block of flux at the right time was a challenge and getting the pigs to the right mix.

I soon realised I could make a few extra pennies doing stuff at home – I bought my first house aged 18 – still an apprentice (hard times). Having bought an Adana from an old lady who had no idea what it was I went on to create what I thought was a mini empire only to be outpriced by my work colleague Sam who had a Heidleberg platen windmill in his garden shed. How I envied the machine operators with their big bucks. I was reduced to doing little one-off jobs he couldn’t be bothered to do.

After the four years passed by quickly I went on to the studio where I was taken through the preocesses of creating artwork using Rotring pens – mainly drawing up ledger book artwork. my finest moment came when I designed and produced a brochure for a canal boat company inShobnall, Burton on Trent, using loads of letraset and cut and paste text on the old pink and white paper.

Then I said goodbye to Tresises and joined the ranks of comps at The Trader group of newspapers in Heanor, Derbyshire – a massive jump in wages. A few years later on to the PCs nad hten on to Macs – little details here as it was nowhere near the excitement of hot metal – I was missing my comping stick and planing mallet.

Where am I today . . . . .working for Northcliffe as Assistant Regional Production Editor – poncy title , I know, but it pays the bills – just. In between I had a couple of years in Turkey on an ex-pats newspaper . . The Post.

Would love to join the letterpress revolution if it ever comes around when these mundane processors of wordage become defunct. Here’s hoping

Cheers

PS Massive thanks to Ken Berwick at Tresises for teaching me all I know.

When the Letterpress revolution begins I’ll be there with you! Brought back a few more memories for me there too Mark, especially re the dangers of the hot metal pot! Thanks for your own memories, very nostalgic!

Enjoyed reading about our lunchtime kick abouts, must get in touch.

Last time I saw you was at a Runrig gig.

Andy

HI Andy, it’s really nice to hear from you, thanks for dropping by. I hope you are doing well.

I was asking Johnny Vol how you were faring when I saw him last. I understand he’s often in the Lincolnshire Poacher around nine on Saturday evenings to meet Bobby Doughty and others and that’s where I occasionally see him.

There were plenty of fun times in those days in spite of everything and those are the days I will invariably remember. Hope you feel the same way. Some characters eh?

Drop a line if you ever fancy meeting Vol one night and I’ll do my best to be around.

Take care.

Stu

I read the above with a smile on my face, I was one of the last apprentice comps in Mansfield and attended day release at South Notts. college. When I first started in the comp room It took a while for me to work out why the caster operator had no front in his shirt. I remember running to the other end of the shop at the first splash back

Happy days eh Mark. 🙂 Caster Operator was the least desirable position in our comp room for the stated reasons! Those splashes could get pretty wild as I recall and I was inevitably on the end of one or two. I remember when hot metal was flying in very direction that the advice was to ‘get down low’ to try and reach the machine to turn it off. Took a daredevil attitude to do that though!

Good to hear from another ex-comp.

Stu

wonderful reading, I too was a Hot Metal Comp, probably one of the last batch, 1978-82 at Matthew Boulton in Birmingham, before the ‘modern era’ took over. I like yourself was shown the way by an older comp Dave Fell, who is no longer alive. Still in the industry as an artworker and still have the need to work to exact measures, no ‘codging it’. Thank you for your insights

Thanks Stuart, nice to hear from another former Hot Metal Comp. The ‘gentlemen of the trade’ as we used to call ourselves! There was an awful lot to be learnt in so many ways from these older, more experienced journeymen and it was a good idea to always listen when they spoke, I found.